Aluminum Castings Explained: Trick Perks and Providers for Your Manufacturing Requirements

Light weight aluminum spreadings play a substantial duty in contemporary production. Their light-weight and durable nature makes them appropriate for various applications. Industries such as auto and aerospace take advantage of their adaptability. Comprehending the advantages and the manufacturing procedure of aluminum castings is essential. Furthermore, selecting the appropriate company can affect high quality and performance. What variables should be considered when choosing a light weight aluminum casting solution? Exploring these aspects discloses essential insights.

Benefits of Light Weight Aluminum Castings

Aluminum spreadings supply numerous benefits that make them a favored selection in numerous markets. One of the primary benefits is their lightweight nature, which significantly lowers delivery and managing expenses. In addition, aluminum shows excellent deterioration resistance, making certain durability and lowered upkeep for items made from this product. The convenience of aluminum enables intricate designs and intricate shapes, giving makers with greater flexibility in production.

Furthermore, light weight aluminum castings have excellent thermal and electrical conductivity, making them suitable for a variety of applications requiring heat dissipation or electrical components. The product likewise has a high strength-to-weight ratio, enabling the production of long lasting yet light-weight parts. Aluminum can be recycled without losing its residential properties, promoting sustainability in producing procedures. In general, these advantages make aluminum castings a trustworthy and reliable option for makers seeking top quality and performance in their products.

Applications of Aluminum Castings in Various Industries

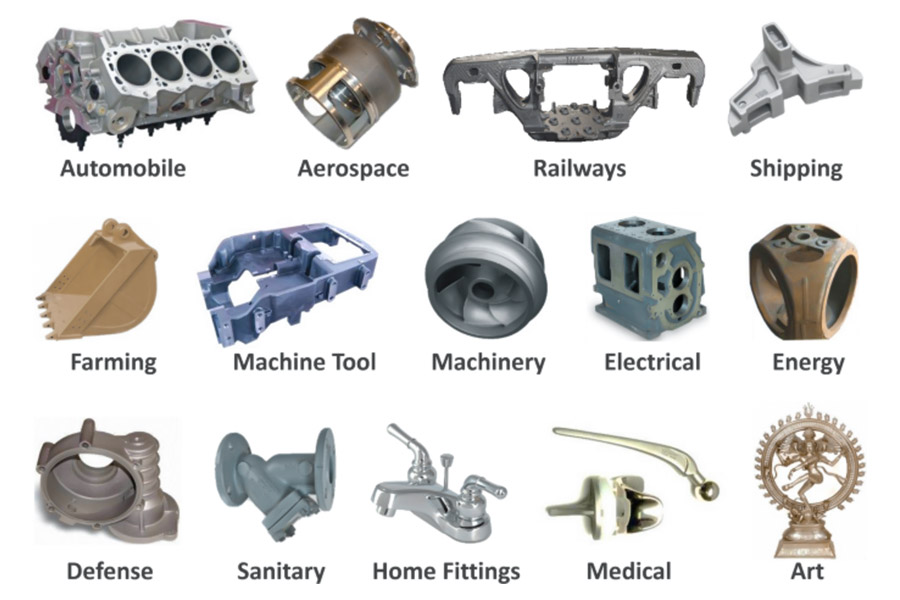

The benefits of aluminum castings make them extremely searched for across various industries, consisting of auto, aerospace, and durable goods. In the vehicle field, they are used for engine blocks, transmission situations, and wheels due to their lightweight nature, which boosts gas efficiency. Aerospace applications benefit from aluminum castings in architectural parts and real estates, giving stamina while decreasing weight, crucial for flight performance.

In customer items, aluminum castings are utilized in products such as kitchenware and digital rooms, supplying durability and aesthetic allure (Aluminum Castings). In addition, the electric industry uses light weight aluminum spreadings for warmth sinks and housings, guaranteeing efficient thermal monitoring. The adaptability of aluminum enables complex layouts and intricate geometries, additionally expanding its applications. In general, the varied energy of aluminum castings underscores their significance in modern-day manufacturing, adding to innovation and efficiency across these key industries

The Production Process of Aluminum Castings

Casting aluminum includes numerous important actions that transform raw steel into accurate elements. The procedure begins with the melting of aluminum scrap or ingots in a heating system, getting to temperature levels around 1,200 ° F. When molten, the aluminum is poured right into a mold and mildew, which can be made from sand, metal, or ceramic, depending upon the wanted specs.

After pouring, the steel solidifies and cools down, creating the form of the mold and mildew (Aluminum Foundry). The following action entails eliminating the casting from the mold and mildew, which may require additional techniques to assure a smooth surface area finish

Subsequently, any type of excess material or blemishes can be machined or ground off to achieve the last dimensions. Quality examinations are after that carried out to confirm that the casting satisfies needed requirements. This meticulous procedure permits makers to create parts that are lightweight, long lasting, and appropriate for a wide variety of applications.

Picking the Right Light Weight Aluminum Casting Solution

When picking a light weight aluminum casting service, it is vital to ponder several elements that can substantially affect the high quality and performance of the end product. First, the solution company's experience and experience in aluminum casting play a vital function in ensuring top notch results. Business should examine the supplier's portfolio and previous tasks to evaluate their capacities.

Additionally, evaluating the modern technology and equipment used by the casting solution is very important, as modern equipment can enhance accuracy and minimize preparations. An additional essential element is the capability to use personalized options customized to specific project requirements, which can substantially boost item efficiency.

Communication and client support ought to not be overlooked; a collaborative companion can help with smoother project implementation. Thinking about cost-effectiveness without compromising high quality is important for making an informed decision. By meticulously evaluating these facets, suppliers can choose a spreading solution that best satisfies their demands.

Future Patterns in Light Weight Aluminum Casting Modern Technology

As manufacturers progressively focus on high quality and performance, advancements in aluminum casting innovation are readied to transform the sector. Emerging patterns include the adoption of automation and robotics, which improve accuracy and decrease human error in casting processes. Furthermore, the assimilation of expert system and artificial intelligence is expected to optimize manufacturing timetables and boost quality assurance.

Sustainability stays a central emphasis, with advancements in recycling techniques enabling you could try this out a lot more efficient reuse of light weight aluminum scrap, thus minimizing waste and energy usage. Advanced simulation software program is additionally obtaining grip, allowing engineers to more tips here version and predict casting performance prior to real production, reducing expensive errors.

Additionally, the development of brand-new alloys and advanced casting methods, such as 3D printing, will certainly expand the possibilities for light-weight yet resilient components. Together, these trends show a vibrant future for light weight aluminum spreading, driven by technological improvements that focus on item, performance, and sustainability high quality.

Often Asked Questions

How Do Aluminum Castings Compare to Various Other Materials?

What Are the Weight Limitations for Light Weight Aluminum Castings?

Weight restrictions for light weight aluminum castings commonly depend on the design and application, however they generally sustain lots capacities varying from a few ounces to numerous tons. Certain restraints emerge from factors like wall surface density and structural honesty.

Can Light Weight Aluminum Castings Be Repaired After Manufacturing?

Light weight aluminum castings can be repaired after production, making use of methods such as welding or epoxy bonding. The feasibility of fixings relies on the level of damages and the certain residential or commercial properties of the aluminum alloy made use of.

What Finishes Are Available for Light Weight Aluminum Castings?

Different surfaces are offered for light weight aluminum spreadings, consisting of anodizing, powder finish, painting, and sprucing up. These finishes improve look, offer corrosion resistance, and enhance surface toughness, dealing with linked here diverse aesthetic and practical needs in making applications.

Just How Do Environmental Regulations Affect Aluminum Casting Processes?

Ecological guidelines significantly affect aluminum casting procedures by mandating stricter emissions controls, urging reusing methods, and advertising lasting products. These policies urge makers to adopt cleaner innovations and lower their eco-friendly impact in manufacturing activities.